Your Global Automation Partner

Probably the Best Fluid Sensor Family for Pressure, Temperature, Flow and Level.

Sounds boastful? Judge for yourself. No other automation manufacturer has developed fluid sensor technology that detects all four measured variables—flow, pressure, temperature and level—with a sensor family from a single source.

A sensor generation that is free from the legacy of its predecessor products – committed solely to the requirements and applications of our customers.

The result is an intuitive operating concept across all types of devices that makes commissioning and handling easier than ever before. The absence of mechanical buttons also meant we were able to design an extremely robust housing with protection class IP69K. Modular process connections allow customer-specific combinations of the frontend, sensor unit and backend within short delivery times. The sensors provide additional information for condition monitoring or sensor-to-cloud solutions via IO-Link in order to exploit the full potential of the sensor family.

Fluid+ – the next-generation sensor family.

Five Sensors – One Operating Concept

The philosophy behind the Fluid+ sensor platform is: Everything that can be designed uniformly is implemented uniformly. This creates resources for unique, innovative solutions that make each of the five sensors better than comparable individual devices. The jury for the iF Design Award also shared this opinion.

Fluid+ White Paper

Concise answers to specific questions about automated fluid detection and monitoring can be found in our Fluid+ family white papers.

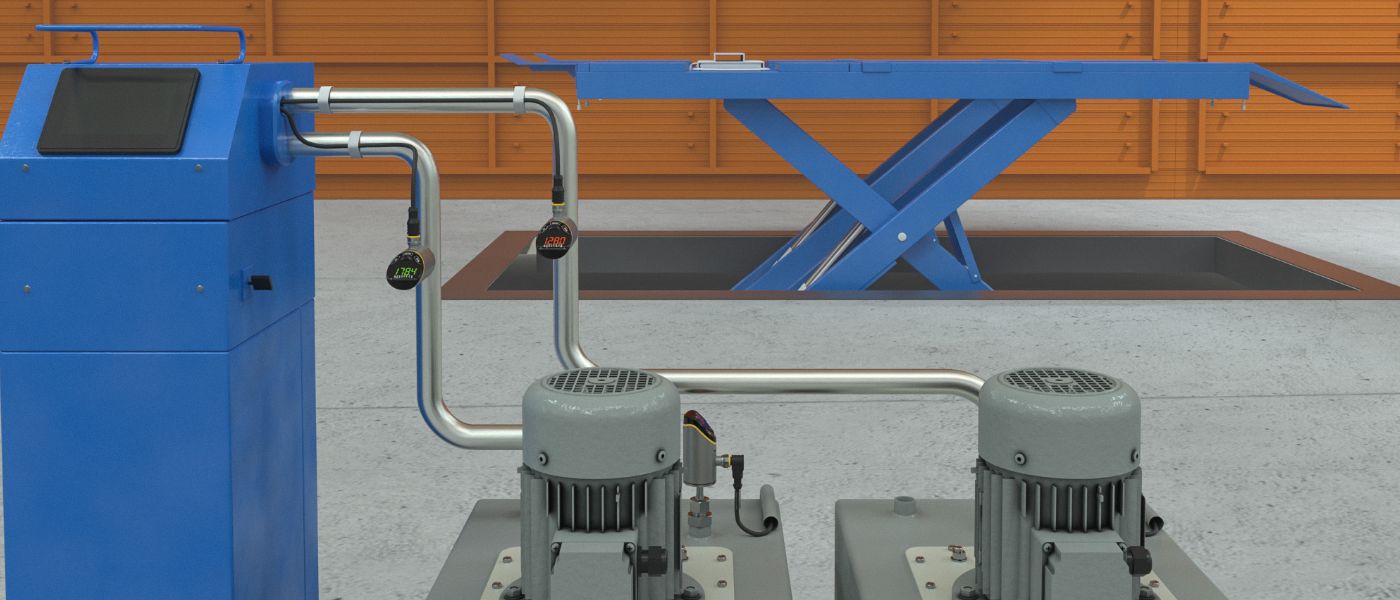

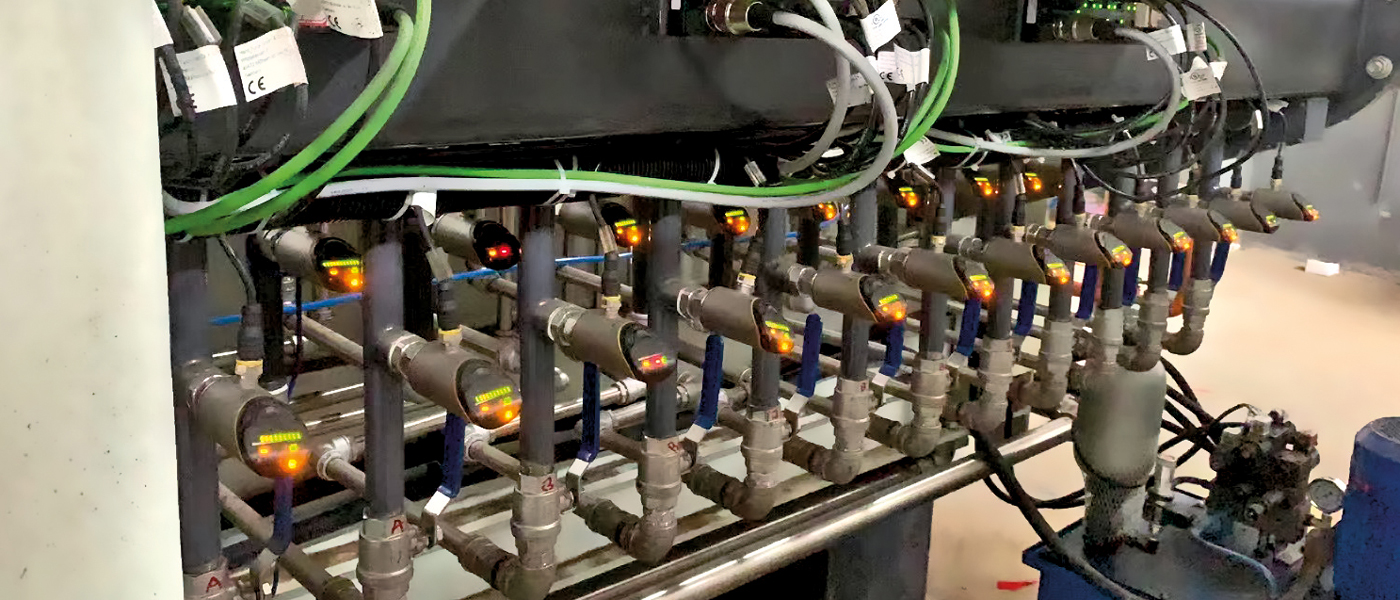

Fluid+ Sensors in Practice

The example applications show how users benefit from the advantages of the Fluid+ sensor family – in a way that is clear, practical and to the point.

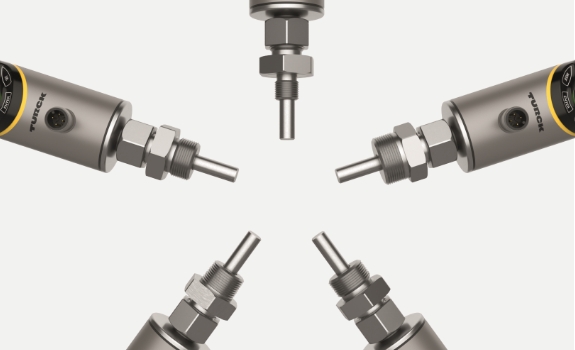

Family Album: Five Individual Talents in the Picture

PS+ pressure sensors

The PS+ series is designed for pressure ranges up to 600 bar and is available with proven ceramic measuring cells (PS310) as well as metal measuring cells (PS510). The differential pressure variant with dual process connection makes it easier to record pressure differences with one device.

TS+ temperature sensors

The TS+ sensors are available as TS700 compact units with an integrated temperature sensor or as TS720 with a separate evaluation and display unit for connecting resistance thermometers or thermocouples. The sensor automatically detects which type of temperature sensor is connected.

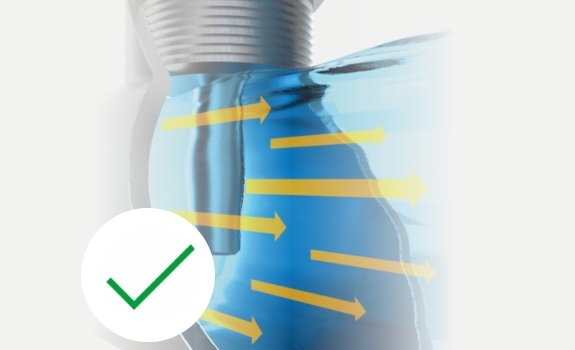

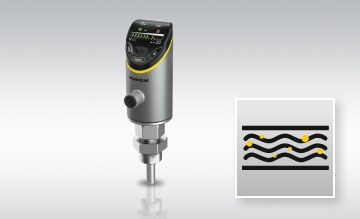

FS+ flow sensors

The FS+ ensures reliable and fast commissioning with the Quick-Teach and Delta-Flow-Monitoring functions. In addition to the flow, it can also output media temperature values, which in many applications eliminates the need for additional temperature sensors.

LUS+ ultrasonic level sensors

THE LUS+ reliably records levels in the range of up to 0.4 or 1.3 meters. It can withstand pressures from 0.5 to 5 bar at the process connection. The measured values can be displayed and output as residual volumes in a user-friendly way by assigning parameters to the existing container geometry.

LRS+ radar fill level sensors

The LRS+ series was developed to measure levels in the range of 0.35 to 10 meters. In contrast to optical or ultrasound-based level sensors, the LRS+ also provide reliable measured values despite interference factors such as dust, wind or light. The Turck radar monitor can be used to simply hide interference signals.

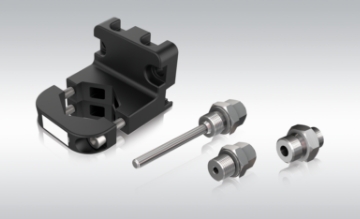

Fluid+ accessories

The comprehensive range of accessories for the Fluid+ platform shows that this device family has been consistently thought through. Our product database contains matching mounting brackets, protective tubes, cooling sections, connecting cables and much more for each individual product.

Ask an Expert

If you have any questions about the Fluid+ sensor family or a specific device, please use our contact form. Our experts will be happy to advise you.

Our Experts