Your Global Automation Partner

Digitize your Flow of Goods with RFID Systems

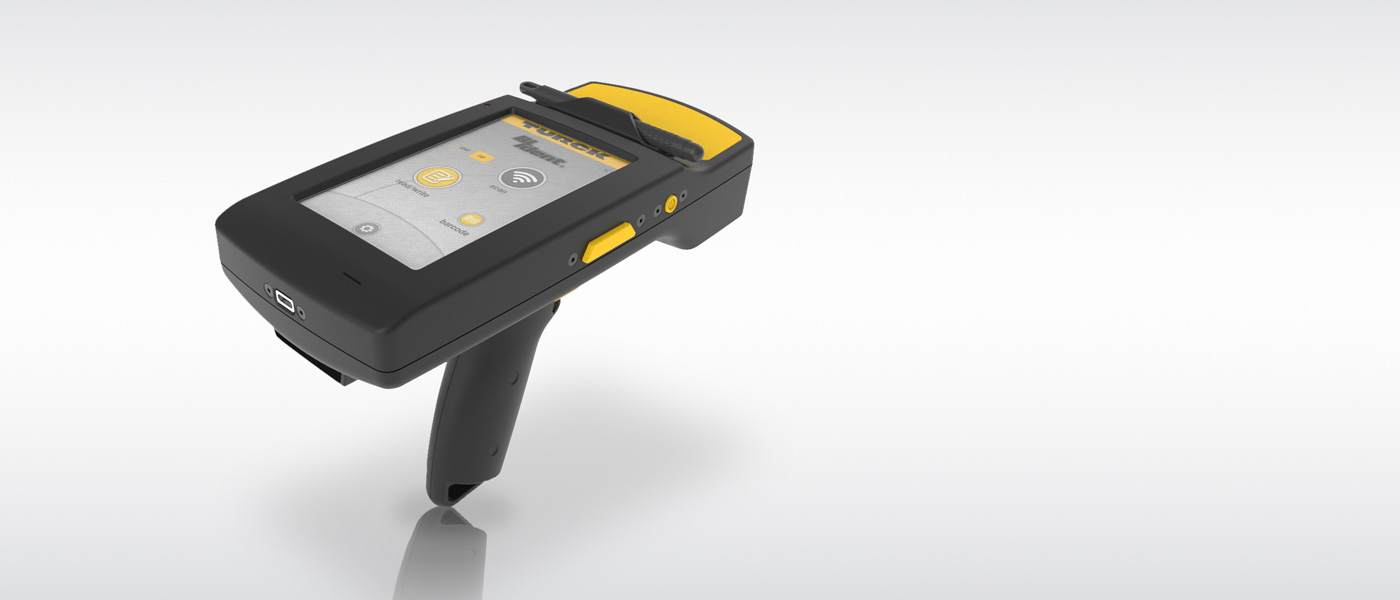

From incoming goods, through production, to the retailer: RFID systems ensure the automatic identification and localization of goods. Use Turck's versatile Q300 UHF read-write head with integrated I/Os and Power-over-Ethernet (PoE) to reliably detect RFID tags. Connecting external antennas expands the RFID reader's application spectrum: from long-range identification to bulk readings, multiplex gate systems and position-accurate detection at item level.

End-to-end Identification of Vehicle Skids

Vehicles must be tracked throughout their entire production process: from body construction to the painting and final assembly. For this purpose, Turck offers special high-temperature data carriers that can withstand painting processes up to 230 °C. UHF systems guarantee their reliable identification.

Position-accurate Measurement of Components

If individual components or products are to be detected, classic UHF RFID read-write heads "see" too many tags. The irrelevant data carriers would then have to be sorted out by filtering or algorithms. Read how the Q300 solves this task more efficiently with external near-field antennas.

Multiplex Operation with External Antennas

Fast and reliable detection of goods at gates: made possible by Turck's Q300 UHF RFID read/write head in multiplex operation of connected antennas. See how the reader detects multiple tags "on-the-fly" even when passing through at high speed – irrespective of their location, condition and distance.

Webinar – How to Optimize your Logistics Using RFID Gates

Whitepaper: Six Factors to Consider When Choosing the Appropriate RFID UHF Tag

Find the right RFID tag for your project with our whitepaper. What influence do material, design, temperature and other aspects of your application have on the choice of the right data carrier?

In the Video: Turck’s RFID Solutions

See how the end-to-end RFID system tracks the flow of materials from stocktaking to outbound goods.

We look forward to your project!

You want to digitalize your intralogistics, get to know innovative RFID solutions for production processes or solve another application problem? Then talk to our specialists for identification systems: Bernd Wieseler and Hendrik Schnabel from the Turck product management RFID systems.

Our sales experts are of course also available for you: