Selective asparagus harvesting with autonomous robot

AvL Motion is breaking new ground – with a machine for the selective harvesting of white asparagus, 'garnished' with high precision sensors as well as RFID and fieldbus technology from Turck

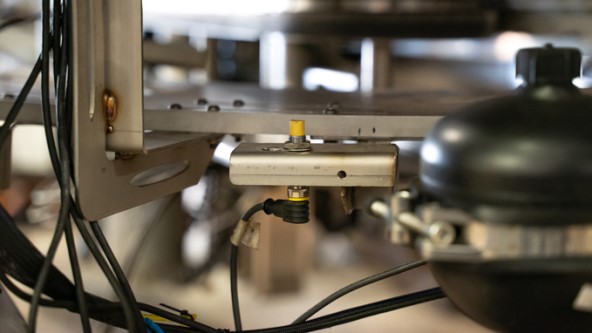

The Dutch startup company AvL Motion put on the market a machine for the fully autonomous selective harvesting of white asparagus. In its search for an ultrasonic sensor for height control, the company came across the IO-Link compatible RU40U from Turck. Through the subsequent collaboration more sensor technology was integrated in the vehicle, including miniature inductive proximity switches, precise encoders as well as LE550 laser sensors from Banner Engineering and the robust Li500-Q25 linear position sensor. AvL also uses the TN-Q14 RFID read/write head for the identification of harvesting modules, while the TBEN-S2-4IOL compact I/O module transfers IO-Link signals to the PLC.

Height control via ultrasonic sensor with IO-Link

AvL Motion uses two of the ultrasonic sensors RU40U with IO-Link to measure the distance between the asparagus bed and the pneumatically controlled internal frame of the machine. In spite of the partly dusty or rain-slicked subsoil, the sensors enable a stable measurement of the height, which users can set on an HMI. “Turck impressed us with the outstanding quality and fast delivery of their product. We therefore stayed with the manufacturer for other components,” says AvL CEO Arno van Lankveld.

Optical process replaces trained eye

The harvesting process of the AvL Compact S1560 is very dynamic. Once the machine is positioned and set in motion, the surface of the soil is scanned. The precise location of an asparagus tip is detected by the main controller through the use of laser sensors, together with an additional optical process. A variable number of harvesting modules move in the process round a circular track inside the robot. At present, this consists of twelve of the around 25 centimeter high cassettes. They are adjusted to the speed of the robot and control the entire process of inserting, cutting and gripping.

Fine tuning between target and harvesting module

The controller not only needs the coordinates of the selected asparagus spears to fine tune the harvesting process, but also a continuous flow of information on the position and movement of the modules. This starts with the query of how many cassettes are currently located in the buffer, i.e. how many are in park position, and those currently detecting an asparagus shoot in the circuit. For this AvL uses the tiny BI3-M08K inductive sensors. The exact identification of the harvesting modules is implemented with RFID – using the TN-Q14 HF read/write head, which reads the individual code of each cassette. Added to this is the position detection provided by a rotary encoder.

Inductive sensor triggers a timer

Once a harvesting machine starts its circuit, this passes a type NI10U-M12 uprox proximity switch, which sets the running of the timer for the harvesting process in the PLC. As the asparagus spears do not grow in tidy rows, the harvesting modules can also move left or right in addition to their movement round the circular track. This is driven with compressed air and is therefore always delayed by a few tenths of a second. In order to nevertheless ensure the correct alignment of the cassettes, the PLC obtains information about the distance between the initial and target position of the modules, measured with LE550 laser sensors from Turck's optoelectronics partner Banner Engineering.

Turning maneuver by joystick

Operators use an external control module to control the speed and the hydrostatic steering of the harvesting machine. Two Turck encoders measure the wheel revolutions; AvL uses an inductive linear position sensor to measure the wheel position. For this the positioning element of the LI500-Q25 sensor is linked with the piston of the steering cylinder. In this way, the main controller calculates the angle of both wheels using only one value – and operators can turn the machine easily with a joystick. Unlike the models offered by the competition, farmers do not have to attach the AvL Compact S1560 to a tractor.

Further Information

- Video (YouTube): The Fully Autonomous White Asparagus Harvesting Robot

- At a Glance: Encoder Portfolio for Numerous Industrial Applications

- Link to the Product: Ultrasonic Sensor RU40U-M18E-LIU2PN8X2T-H1151

- Link to the Product: Inductive Sensor NI10U-M12-AP6X-H1141

- Link to the Product: Inductive Linear Position Sensor LI500P0-Q25LM0-LIU5X3-H1151

- Link to the Product: HF-RFID Read/write Head TN-Q14-0.15-RS4.47T

- Link to the Product: Compact Multiprotocol I/O Module TBEN-S2-4IOL

- Download Whole Article – more12050e [PDF, 1,31 MB]

- Automotive

- Modular Flexibility and Safety in Filter Production

- Cable with Integrated Current Monitoring Prevents Unwanted Shutdown of Conveying System

- Inductive Couplers Ensure Precise Material Feed

- Assembly Management with a Direct MES Connection

- Body Detection in Automobile Production

- Reliable Skid Detection in Automotive Production

- Error-free JIS Order Picking for Bumpers

- RFID Bus Mode Ensures Quality of Lithium-Ion Batteries

- Level Control in Central Lubrication System

- Quality Assurance on the Gluing Robot

- Tilt angle sensor accelerates platform alignment

- Motor Control with Condition Monitoring

- IP67 Hybrid Module Processes Safety Signals

- Decentralized monitoring of cooling stations

- Robot welding cells networked with Ethernet

- Monitoring the cooling circuit on welding clamps

- Flow monitoring in drum washers

- Condition Monitoring of Motors

- Press Shop – Tool Identification

- Body Shop – Welding Nut Detection

- Paint Shop – Skid Identification

- Final Assembly – Robot Assembly

- Powertrain – Contactless Verification

- Item-level Detection with UHF RFID

- Supply of cooling lubricant in machine tools

- Press Shop: Controlling hydraulic pressure

- Measuring process pressure on scissor lifts

- Success Stories

- RFID Solution for Data Acquisition in Stator Production

- Modular Plant for Flexible and Efficient Production

- Decentralized Safety Technology for Modular Production

- Modular Conveyor System

- RFID and I/O Modules for Safe Tool Changes

- RFID Guides AGV in Suspension Production

- IO-Link Wired Silencer Production

- Workpiece Carrier Identification in Rear Vent Production

- Weld Nut Sensing

- RFID Traceability

- RFID in Engine Production

- Bumper Production with Identification

- Solutions for Paint Shops

- Welding and Assembly Sensors

- Angle Sensors for Assembly Systems

- Tool Identification

- RFID Identification of Injector Nozzles

- RFID in the Body Shop

- IO-Link Eases Differential Gear Production

- Chemical

- excom I/O System Enables Safe Hydrogen Liquefaction

- Decentralized Automation in Ex Areas

- RFID Control of Tube Connections in the Ex Area

- Ethernet Signal Connection in the I&C Room

- Ethernet-based Automation of Modular Skids

- Ex Isolation in Modular Process Plants

- Detection of Pigs

- Remote Signal I/O

- Easy Connection of Field Devices

- Signal Processing with System I/O in the Control Cabinet

- Signal Separation with Interface Technology in the Control Cabinet

- Identification of Hose Connections

- Efficient Monitoring of Cabinets in the Field

- Monitoring of Quarter Turn Actuators

- Planning and Assembly of System Solutions

- Success Stories

- Control Cabinet Monitor for Transmission of Condition Data

- Efficient Cooling of Industrial Furnaces with Turck's FS+ Flow Sensors

- I/O System Excom Creates Space in the I&C Rooms

- Zone 2 and 22 RFID

- Efficient Testing Control

- Intrinsically Safe Field Communication

- Process Control System Partnership

- Hazardous Area Remote I/O

- Dual Valve Position Feedback

- Flexibility with Fieldbus

- Asset Management with Remote I/O

- Correct Positioning with RFID in Carbide Production

- Compact Ex Protection

- Energy

- Capacitive Sensor Detects Point Level in Pellet Heating System

- RFID System Identifies Solar Cell Carriers

- Decentralized I/O System for Hazardous Areas at H2 Refueling Stations

- Decentralized I/O Solution in Ex Zone for H2-Fueling Station

- I/O Module Facilitates Setup and Mobile Use of Fuel Cell Test Stand

- Wind Turbine Rotor Positioning

- IP67 I/O in Coal Production

- UHF RFID Identifies Switch Gear

- Remote I/O in Biogas Plant

- Food and Beverage

- Condition Monitoring Sensor Automates Climate Control

- Condition Monitoring of Control Cabinets

- Condition Monitoring in Storage Rooms

- Dough Thickness Control in Rolling Machines

- Identification of Food Containers

- Quick Sensor Replacement in Beverage Plants

- Detection of Pipe Elbows

- Identification of Chocolate Moulds

- Success Stories

- Cloud-based Maintenance for Steam Generators

- RFID Support Enables Track and Trace in Food Production

- Reliable Linear Position Detection in Ex Zone 22

- Decentralized Control Modules in Coldstore

- Track and Trace in Meat Production with RFID

- Contact-free Encoder in Potato Production

- UHF RFID in Food Distribution Center

- RFID for Chocolate production

- Distributed I/O for Food Equipment

- Remote I/O for Distilleries

- RFID and Autoclaves

- Transparency in Chocolate Manufacturing

- IP67 Power Supplies for Conveyors

- Identification in Food Product Storage

- Logistics

- UHF RFID Tunnel for Goods Identification on Conveyor Belts

- Preventing Package Jams in the Logistics Center

- Height Control and 3D Spatial Monitoring on Autonomous Forklift Trucks

- Decentralized Control of Conveyor Modules

- Tracking Big Bags with RFID

- Distance Detection in Container Cranes

- Access Control for Protected Areas

- I/O Blocks Control Roller Conveyor Modules

- Fast Tag Detection at Warehouse Gates

- Item-level Detection with UHF RFID

- Preventive Maintenance on Conveyor Belts

- Detection of Transport Containers

- Level Detection in Vessels

- Identification of Cryovessels

- Identification of Mobile Containers with Handheld Devices

- Identification of Food Containers

- Tier 1 – Bumper Identification

- Condition Monitoring in Storage Rooms

- Collision Protection on Reach Stackers

- Success Stories

- Efficient Solution for the Digitalization of Conveyor Technology

- Logistics: RFID Reduces Error Quota by 99 Percent

- ROI After Three Avoided Delivery Errors

- Sustainable Tracking of RTIs thanks to RFID

- RFID with HF Bus Mode Eases Seed Storage

- RFID Enables Unmanned Store at Major Building Site

- I/O and Safety Modules Increase Throughput in Intralogistics

- Shipment Tracking for Raw Materials

- RFID-Based Tracking Solution for Loading Error Minimization

- RFID-based Tracking of Inbound and Outbound Materials

- Decentralized UHF RFID Solution

- Contact-free Encoder in Potato Production

- Decentralized Control Modules in Coldstore

- IP67 Power Supplies for Conveyors

- Modular Conveyor System

- RFID Solution for Warehouse

- RFID Guides AGV in Suspension Production

- RFID Identifies Pharmaceuticals

- UHF RFID in Food Distribution Center

- Mobile Equipment

- Animal and Object Detection on the Combine Harvester

- Condition Monitoring Sensor Automates Climate Control

- Automatic Slope Compensation

- Distribution Lines for Field Sprayers

- Angle Measurement on a Field Sprayer

- Determining the Boom Angle Position

- Two-Axis Tilt Measurement on a Combine Harvester

- Collision Protection on Reach Stackers

- Success Stories

- RFID Solution with Smart Forklifts in Autombile Production

- Safe Remote Maintenance of Irrigation and Drainage Pumps

- Access Control with RFID System

- Selective Asparagus Harvester

- Position Measurement with RFID and Encoder

- RFID Guides AGV in Suspension Production

- Block I/O Modules on Super Yacht

- Wear-free Encoder on Hopper Dredger

- I/O for Dust Suppression

- Cabinet Cooling

- Quick Disconnect Connectivity

- Automation Solutions for Extreme Cold

- Remote I/O for Cranes

- Rugged Heavy Metal Lifting

- Rollercoaster Positioning

- Mobile Machinery Solutions

- Exact Height Positioning

- Critical Angle Sensing

- Angle Sensor Detects Platform Lift

- Oil and Gas

- Packaging

- Decentralized RFID Package Verification

- Identification of Printing Color Cartridges

- Reliable Operation of Machines

- Monitoring of Caps in Filling Lines

- Monitoring Changeover Processes

- Identification of Test Bottles

- Level Monitoring of Ground Coffee

- Level Detection in Vessels

- Detection of Transport Containers

- Success Stories

- Pharma

- End-to-End Sample Tracking with RFID

- RFID Control of Tube Connections in the Ex Area

- Decentralized Package Verification

- Automate Modular Skids

- Pharmaceutical Skids with Decentralized I/O Technology

- Ex Isolation in Modular Process Plants

- Control of Valve Interfaces

- Monitoring of Quarter Turn Actuators

- Detection of Pipe Elbows

- Remote Signal I/O

- Planning and Construction of Super Skids

- Easy Connection of Field Devices

- Identification of Cryovessels

- Identification of Mobile Containers

- Identification of Mobile Containers with Handheld Devices

- Identification of Hose Connections for Precursors

- Identification of Hose Connections in Sterile Areas

- Identification of Hose Connections in Ex Zone 1

- Identification of Big Bags and Bioreactors

- Identification of Single-Use Applications

- Success Stories

- Checking Hose Connections with RFID

- Contacless Transfer of Power and Switching Signals

- HMI Controls Industrial Blender

- BL20 Codesys Gateway Controls Image Processing Machine

- RFID Identifies Pharmaceuticals

- Speed measurement of mixing heads in magnetic stirrers

- Reading Device Detects Different Materials

- Semiconductor

Select Country

Turck worldwide

-turck-image.jpg)

-turck-thumbnail.jpg)